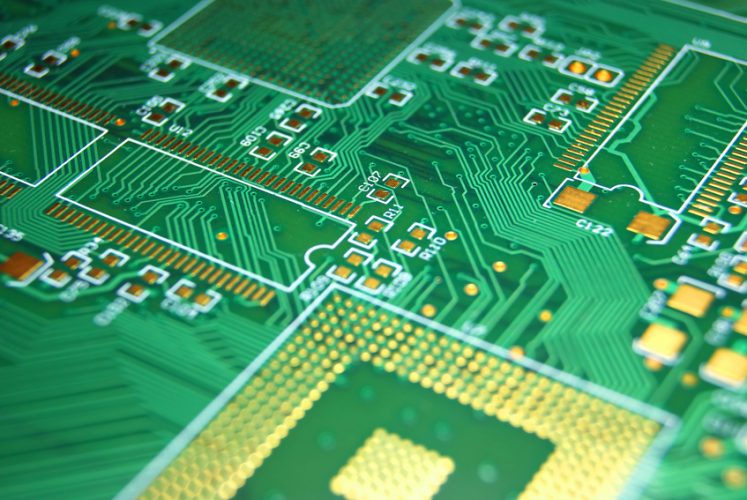

The landscape of electronics is continually evolving, driven by the need for faster, more efficient, and cost-effective solutions. As a prototype PCB manufacturer, staying at the forefront of these developments is essential to meeting client demands and enhancing product quality. This blog explores the latest innovative techniques in prototype PCB design that are shaping the future of the industry.

Design for Manufacturability (DFM)

Design for Manufacturability (DFM) is an essential approach that integrates manufacturing considerations into the PCB design process. This technique ensures that designs are not only functional but also optimized for the manufacturing environment. By considering factors like material selection, component placement, and assembly processes during the design phase, engineers can significantly reduce production costs and lead times.

Benefits of DFM:

- Reduced Errors: By anticipating potential manufacturing issues, DFM minimizes the risk of errors that can lead to costly revisions.

- Faster Prototyping: When designs are tailored for manufacturability, prototype PCB manufacturers can produce boards more quickly.

- Cost Savings: Optimized designs can lower material waste and simplify assembly, resulting in significant savings.

Incorporating DFM principles into prototype PCB design is a forward-thinking strategy that can streamline production and enhance product reliability.

Advanced Simulation Tools

Simulation tools have revolutionized the way prototype PCB manufacturers approach design. By allowing engineers to create virtual models of their designs, these tools enable thorough testing and optimization before any physical prototypes are produced. Common simulation techniques include:

- Electrical Simulation: This technique allows designers to analyze how signals will behave in a circuit, identifying potential issues like signal integrity or electromagnetic interference.

- Thermal Simulation: Understanding how heat dissipates within a PCB is crucial for preventing component failure. Thermal simulations can help engineers design for optimal heat distribution.

- Mechanical Simulation: By assessing the mechanical stresses that a PCB may encounter during operation, engineers can design boards that withstand environmental factors and physical stresses.

The use of advanced simulation tools in prototype PCB design not only accelerates development timelines but also ensures higher-quality final products.

3D Printing for Prototyping

3D printing technology has found its place in the PCB prototyping process, offering unprecedented flexibility and speed. This innovative technique allows prototype PCB manufacturers to quickly produce complex geometries that traditional manufacturing methods might struggle with. The key advantages of using 3D printing for PCB prototypes include:

- Rapid Iteration: Designs can be modified and printed in a matter of hours, allowing for quick iterations based on testing and feedback.

- Complex Geometries: 3D printing can produce intricate designs that are difficult or impossible to achieve through conventional methods.

- Reduced Material Waste: The additive nature of 3D printing means that material is used only where necessary, leading to less waste compared to subtractive manufacturing processes.

By integrating 3D printing into the PCB prototyping process, manufacturers can significantly shorten development cycles and enhance design capabilities.

Flexible PCBs

The demand for flexible PCBs is on the rise, driven by the growing need for compact and lightweight electronic devices. Flexible PCBs are made from pliable materials that allow them to bend and conform to various shapes and spaces. Some of the benefits of using flexible PCBs include:

- Space Efficiency: Flexible designs enable more compact electronics, making them ideal for wearable technology and portable devices.

- Weight Reduction: Lighter materials contribute to overall weight savings in devices, enhancing portability.

- Durability: Flexible PCBs are often more resilient to shock and vibration, making them suitable for harsh environments.

As a prototype PCB manufacturer, embracing flexible PCB technology can open up new opportunities in various industries, including consumer electronics, automotive, and medical devices. For further exploration of flexible PCB applications, click this link here now.

Internet of Things (IoT) Integration

The Internet of Things (IoT) is reshaping the electronics industry, and PCB design is no exception. IoT devices require specialized PCB designs that accommodate various sensors, communication modules, and energy-efficient components. Some key considerations for integrating IoT into PCB design include:

- Compact Layouts: IoT devices often have limited space, necessitating dense component placements and multi-layer designs.

- Low Power Consumption: Energy efficiency is crucial for battery-operated IoT devices. Designing PCBs with low-power components can significantly extend device lifetimes.

- Wireless Communication: Integrating antennas and communication modules into the PCB design is vital for enabling seamless connectivity.

By adopting innovative techniques tailored for IoT applications, prototype PCB manufacturers can position themselves as leaders in this rapidly expanding market.

Automated Design Tools

Automation is becoming increasingly prevalent in the PCB design process. Automated design tools can streamline various aspects of PCB development, such as layout optimization, component placement, and routing. Key advantages of these tools include:

- Time Savings: Automation significantly speeds up the design process, allowing engineers to focus on more complex design challenges.

- Error Reduction: Automated tools can help identify potential design flaws early in the process, reducing the likelihood of costly errors in production.

- Standardization: Automated processes promote consistent design practices, leading to higher quality and more reliable final products.

Implementing automated design tools in the PCB prototyping process can enhance efficiency and improve overall design quality.

Eco-Friendly Materials

Sustainability is becoming a priority in all manufacturing sectors, including PCB production. The use of eco-friendly materials in PCB design is gaining traction as companies aim to minimize their environmental impact. Some eco-friendly alternatives include:

- Biodegradable Substrates: These materials break down more easily than traditional substrates, reducing waste in landfills.

- Lead-Free Components: Transitioning to lead-free solder and components is essential for complying with environmental regulations and promoting safety.

- Recyclable Materials: Designing PCBs with recyclable materials can help facilitate easier end-of-life disposal and reduce overall environmental footprints.

By adopting eco-friendly materials, prototype PCB manufacturers can contribute to a more sustainable future while also appealing to environmentally-conscious consumers.

Conclusion

Innovative techniques in prototype PCB design are transforming the electronics industry, enabling manufacturers to create high-quality, reliable products faster and more efficiently than ever before. By embracing approaches like Design for Manufacturability, advanced simulation tools, 3D printing, flexible PCBs, IoT integration, automated design tools, and eco-friendly materials, prototype PCB manufacturers can stay competitive and meet the evolving demands of the market.

Staying informed about these innovative techniques will not only enhance your capabilities as a PCB prototype manufacturer but also position your business for long-term success.